Инженерное образование играет ключевую роль в развитии промышленности и технологических инноваций. Высшие учебные заведения Москвы, особенно технические вузы, выступают основным катализатором этого процесса, обеспечивая студентов…

Промышленный Университет

Энергоэффективность становится ключевым фактором для устойчивого развития промышленности. В условиях растущего потребления энергии и углубляющегося экологического кризиса повышение энергоэффективности не только является необходимостью, но и…

Развитие образования и промышленности тесно взаимосвязано. Образовательные учреждения играют ключевую роль в подготовке квалифицированных специалистов, в то время как промышленные компании нуждаются в компетентных кадрах…

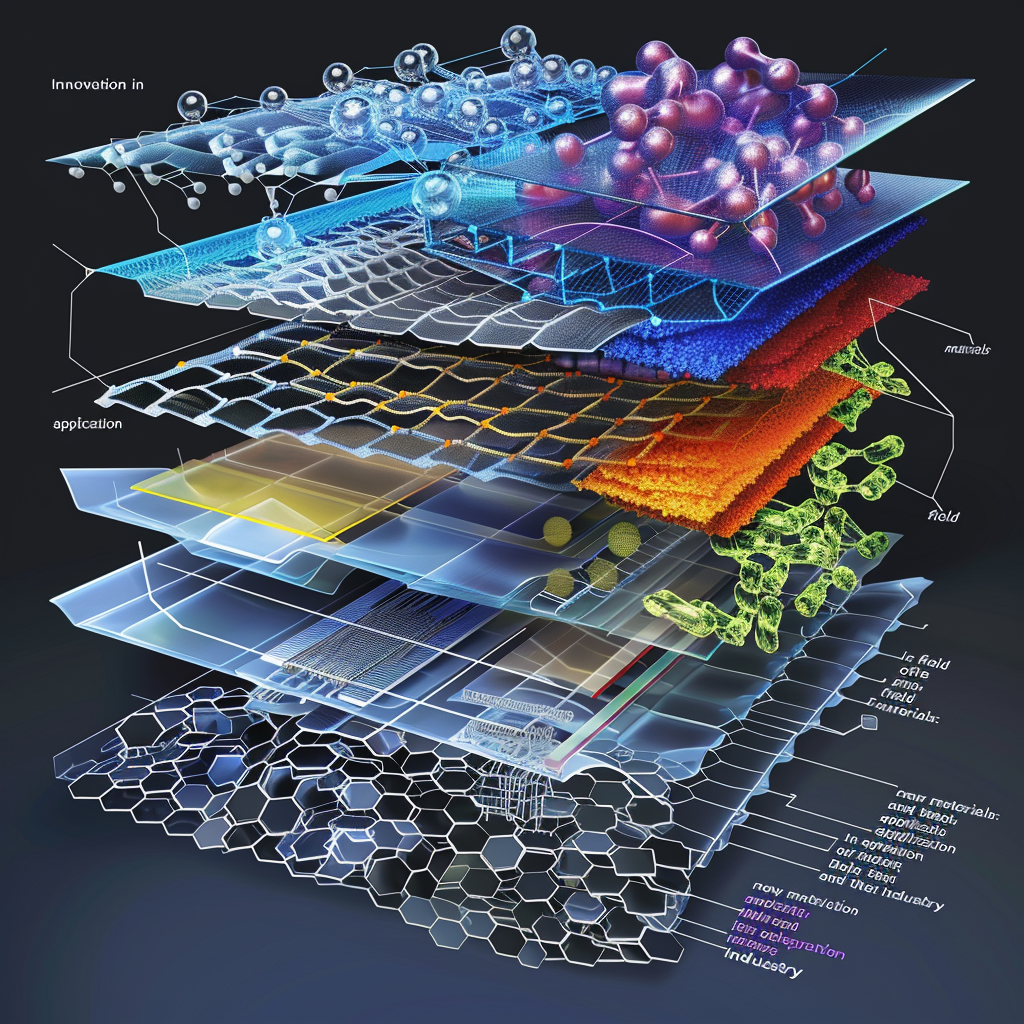

Инновации в области материалов играют ключевую роль в развитии промышленности. Новые материалы не только изменяют технологические процессы и продукты, но и открывают новые возможности для…

В мире произошли значительные изменения в промышленной сфере, вызванные глобализацией. Глобальные рынки, развитие технологий и изменения в культурных стандартах требуют от инженеров не только технических…

Профессиональные навыки становятся все более важными для успешной карьеры в промышленных секторах. Однако, помимо технических знаний и навыков, soft skills, или мягкие навыки, играют также…